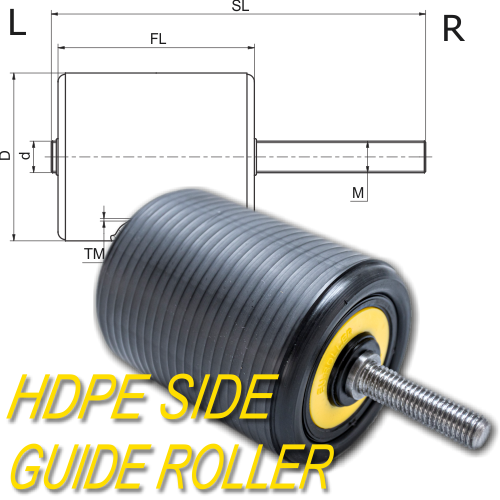

HDPE SIDE-GUIDE Rollers

For various reasons, the conveyor belt may occasionally drift side to side. In such instances, EU-Roller-Guide Rollers with threaded-shaft ends, commonly referred to as belt guide rollers, can be used. Therefore, it is recommended to always use guide rollers on the most suitable transom, the self-centralizing transom, which automatically rotates whenever the belt deviates from the center of the conveyor-line, the guide rollers help the running of the belt parallel to the center of the conveyor-frame.

EU-Roller- Guide Rollers are engineered to perform in extreme temperatures, harsh environments, and highly corrosive, chemical, or coastal conditions that typically cause damage. The roller's main body is HDPE and steel-tube supported. Entirely known for its exceptional resistance to abrasion and sun exposure, fire retardant properties, low friction coefficient, ability to absorb high impact forces, excellent gripping capabilities, and high melting point.

Specifications

Structure & 3D view

HDPE Side-Guide Roller Features

- Applications

- Mines

- Quarries

- Cement plants

- Coal-fired power plants

- Dock installations

- Waste recycling

- Key Benefits

- Non-corrosive

- Excellent abrasion resistance

- Extended lifespan

- Suitable for nearly any applicationwhere steel rollers are used

- Recyclable

- Minimizes damage to conveyor belts

- Watertight sealing arrangement

- Roller designer

- Create with the Roller designer! Design it, and we’ll bring it to life.

- Jump to Roller Designer