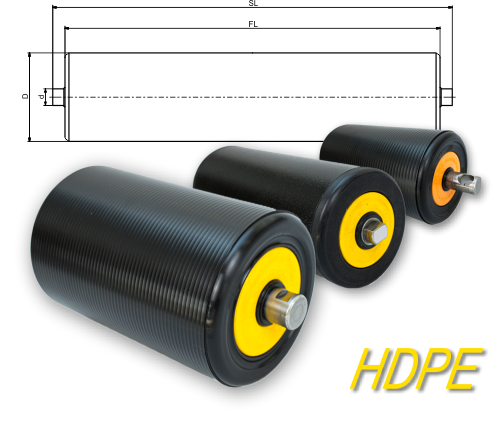

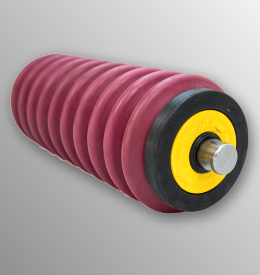

HDPE Rollers

OUR HDPE ROLLERS ARE WIDELY KNOWN AS THE MOST ESTEEMED PRODUCT IN THE CONVEYOR-ROLLER MARKET.

THE EU-ROLLER'S DESIGN DELIVERS EXCEPTIONAL PERFORMANCE AND AN INDUSTRY-LEADING LIFESPAN.

HDPE Rollers represent a breakthrough in reinforced high-density polyethylene (HDPE) conveyor rollers.

Featuring a unique design and incorporating our patented sealing arrangement, bearing and seal housing, and roller shell, HDPE Rollers offer a durable, long-lasting, and environmentally friendly alternative to traditional steel rollers. All plastic components are designed in-house and manufactured at our factory.

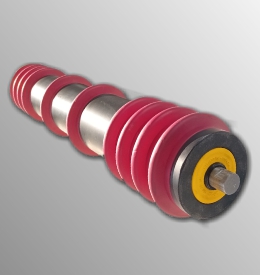

IMPACT Rollers

Impact Rollers are engineered to absorb the force of heavy loads dropping onto the conveyor belts. This lineup of rollers integrates a tested Sealing Arrangement and patented high-density polyethylene (HDPE) Bearing and Seal Housing, ensuring robustness and longevity in demanding conveyor systems.

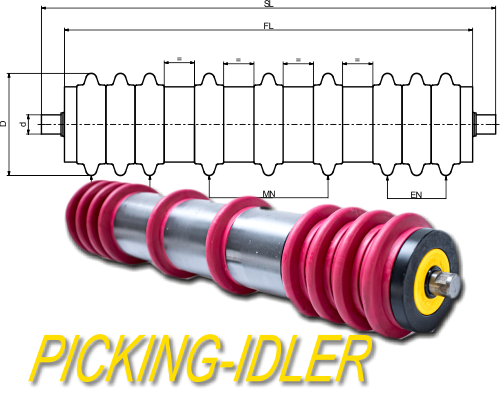

PICKING-Idler Rollers

Picking-Idler Rollers are engineered to absorb the force of conveyor belts. This lineup of rollers integrates a tested Sealing Arrangement and patented high-density polyethylene (HDPE) Bearing and Seal Housing, ensuring robustness and longevity in demanding conveyor systems.

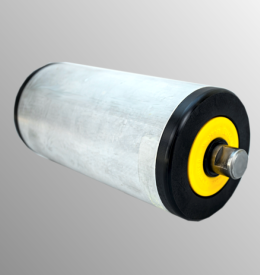

PLASTEEL-PLASALU Rollers

EU- Roller's innovative, designed Steel and Aluminium Rollers are engineered to ensure precise bearing alignment, resulting in smoother rolling, increased efficiency, and reduced noise pollution. These steel and Aluminium rollers, designed to minimize friction, are durable, environmentally friendly, and offer exceptional benefits not previously available in traditional steel rollers.

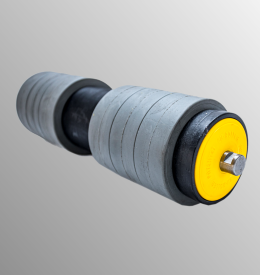

RUBBER DISC Rollers

Rubber disc idlers operate by utilizing durable rubber discs spaced at regular distances along the roller. These discs effectively eliminate conveyor belt carry-back buildup by breaking up material on the return side of the belt, which typically accumulates in the center. The discs are clustered at both ends of the roller to support and protect the belt edges.

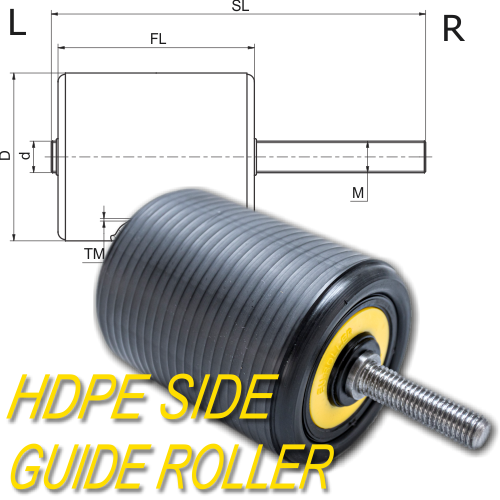

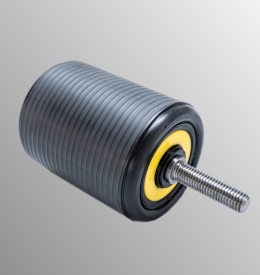

HDPE SIDE-GUIDE Rollers

For various reasons, the conveyor belt may occasionally drift side to side. In such instances, EU-Roller-Guide Rollers with threaded-shaft ends, commonly referred to as belt guide rollers, can be used. Therefore, it is recommended to always use guide rollers on the most suitable transom, the self-centralizing transom, which automatically rotates whenever the belt deviates from the center of the conveyor-line, the guide rollers help the running of the belt parallel to the center of the conveyor-frame.

EU-Roller- Guide Rollers are engineered to perform in extreme temperatures, harsh environments, and highly corrosive, chemical, or coastal conditions that typically cause damage. The roller's main body is HDPE and steel-tube supported. Entirely known for its exceptional resistance to abrasion and sun exposure, fire retardant properties, low friction coefficient, ability to absorb high impact forces, excellent gripping capabilities, and high melting point.